- Home

- /

- Technology

TECHNOLOGY

Customer satisfaction is our benchmark for performance and success. We rely on our extraordinary level of quality and manufacturing know-how in order to achieve our performance criteria of tightest tolerances in dimension, shape, position and surface finishing.

Our qualified team has many years of experience in the professional use of our production technology, guaranteeing you the highest possible precision.

THE FOLLOWING OVERVIEW SHOWS A

SELECTION OF OUR MANUFACTURING PROCESSES

Heat Treatment

- Vacuum furnace

- Plasma nitration

- Inductive heat treatment

- Oxidizing

- Annealing

- Refrigeration

Soft Machining

- Sawing / Cutting

- Drilling / Deep hole drilling

- Turning

- Short lathes

- Long lathes

- Milling

- 3‑axis simultaneous machining

- 5‑axis simultaneous machining

- Electric forging

Hard Machining

- Hard turning

- Hard milling

- 3‑axis simultaneous machining

- 5‑axis simultaneous machining

- Cylindrical grinding

- External cylindrical grinding

- Centreless

- Plunge grinding

- Throughfeed grinding

- Peelgrinding

- Between centres

- Plunge grinding

- Peelgrinding

- Centreless

- External cylindrical grinding

- Non-round / Profile grinding

- Grinding machine with 5‑axis

- CNC flat profile grinding

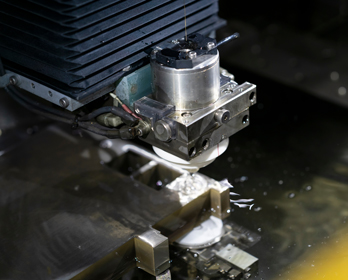

Eroding (EDM)

- Start hole eroding

- Ø 0.2–3.0 mm

- Wire EDM

- Wire-Ø0.02–0.3 mm

Surface Finishing

- Bore honing

- Lapping

- Barrel finishing

- Polishing

- Sandblasting / glassblasting

- Straightening

- Engraving / laser marking

Surface Treatment

- Coatings

- Hard coatings

- PVD, CVD

- Sliding layers

- Oxide layer

- Diffusion layers

- Nitrating

- Electroplated layers

- Chemical coating

Quality Management

- Quality assurance

- Certification DIN ISO 9001

- Recording/documentation

- Management of measuring equipment

- QM technology/measurement and testing technology

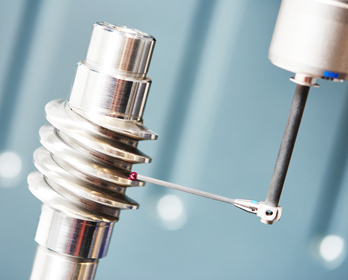

- Tactile measuring methods/multisensor technology

- Length

- Contour

- Roundness

- Parallelism

- Optical measuring methods

- Measuring projectors

- Laser

- Surface measurement

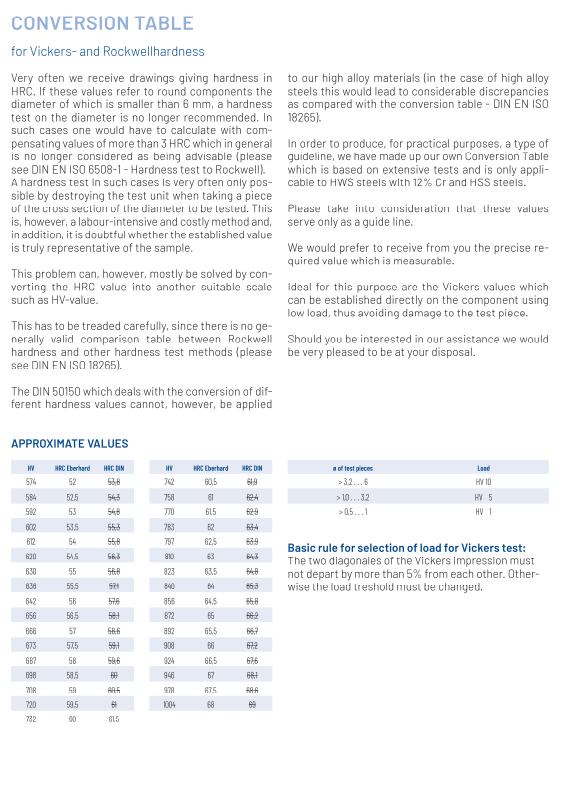

- Hardness test

- Rockwell

- Vickers

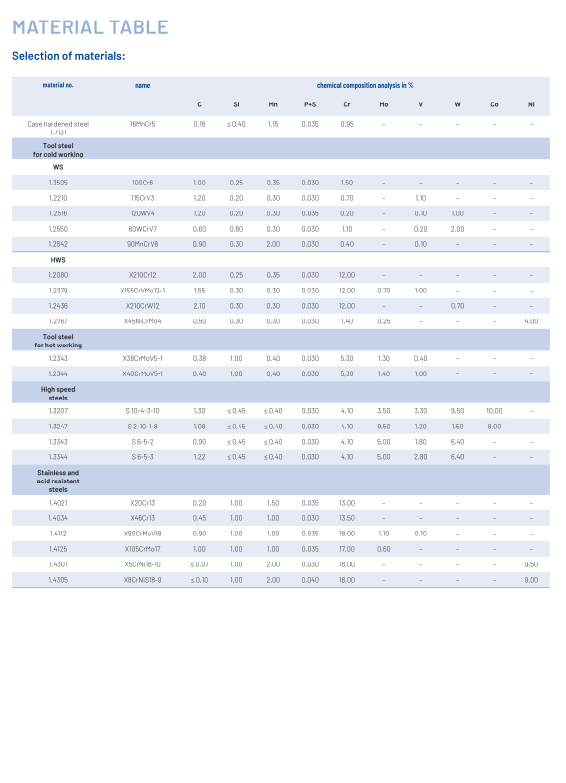

- Material laboratory

- RFA

- Material analyses

- Microstructure investigations

- Test equipment construction

- Tactile measuring methods/multisensor technology

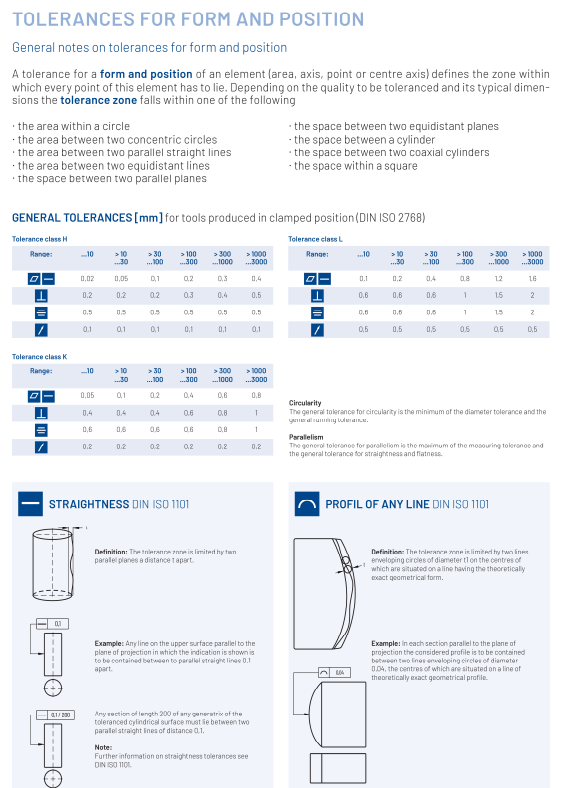

Technical notes